Two-Post vs Four-Post Car Lift: 7 Key Insights for 2026

Prepared for: Architects, Urban Planners, and Parking Design Professionals Purpose: To provide a comprehensive evaluation of two-post vs four-post car lift systems, with emphasis on structural design, mechanical performance, and long-term usability. This report examines both the hydraulic two post car lift and the hydraulic four post car lift, comparing their suitability for multi-level parking solutions, workshop efficiency, and vehicle storage. Key considerations include two post vs four post car lift for mechanics, integration into architectural layouts, regional adoption trends, and return on investment (ROI). The goal is to inform design and planning professionals about the optimal lift system for sustainable, space-efficient, and user-friendly parking development.

Solid Parking

Course Outline

Introduction

As urban centers face increasing parking space scarcity, vertical parking solutions such as two-post and four-post car stackers have emerged as critical infrastructure components. These mechanical lifts extend parking capacity vertically without significant horizontal expansion, offering architects and planners adaptable options for dense environments. Beyond space optimization, these systems influence building design, operational efficiency, and lifecycle costs.This report explores these systems through a multi-dimensional lens, incorporating technical research and market insights, to provide professionals with a data-driven foundation for specifying appropriate car stackers tailored to diverse project needs.Alright, so here’s the deal: parking’s a nightmare these days—cities are getting more jammed, and everyone’s scrambling for space. If you’re an architect or some big-shot developer, or heck, even just running a garage, picking the right car lift isn’t just a nice-to-have. It’s gotta be on your checklist, right up there with “Where’s the nearest coffee shop?”

Now, the two-post versus four-post car lift debate? Oh, it’s real. Two-post lifts—those are the skinny ones that barely take up any room. Perfect if you’ve got a shoebox-sized garage or you’re trying to squeeze every inch out of your workshop. Super handy, but maybe don’t try parking an SUV up there for a year and forget about it.

Four-post lifts, though? Whole different beast. They’re bulkier, sure, but rock-solid. You want to store a car long-term, stack ‘em up, or run a legit mechanic shop where safety’s non-negotiable? Four-post is probably your guy.

Honestly, if you’re wrenching for a living, knowing the pros and cons here isn’t just trivia—it’s how you keep your workflow smooth, your wallet happy, and your insurance guy off your back. This isn’t just another boring spec sheet; think of it more as your cheat code to picking the right lift, with the nitty-gritty details and a few market tidbits thrown in so you don’t end up regretting your choice six months down the road.

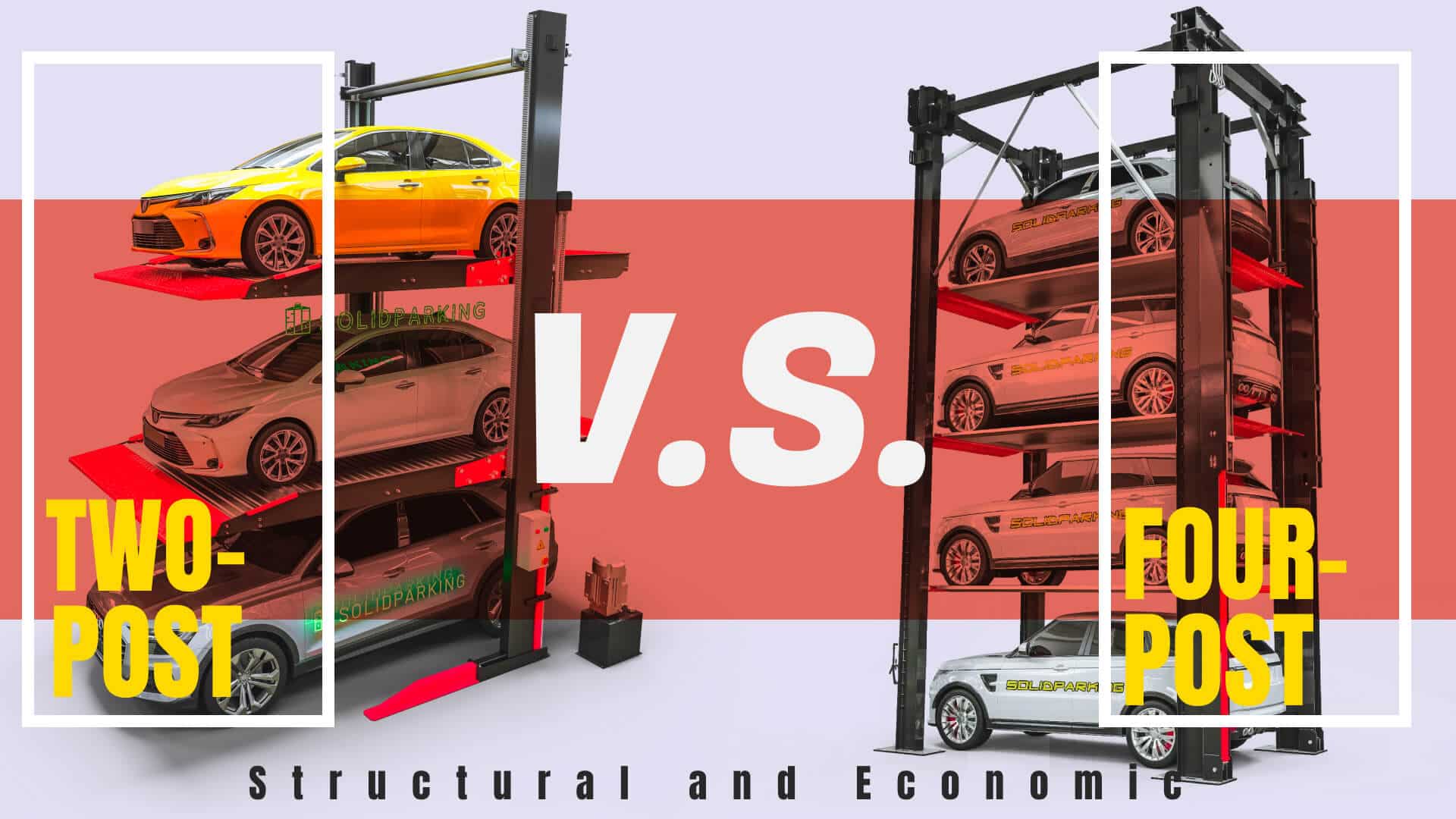

Structural and Mechanical Systems

Structural and Mechanical Insights into Hydraulic Two-Post Car Lift vs Hydraulic Four-Post Car Lift

The core difference between two-post and four-post stackers lies in their post configuration and lifting mechanisms, which significantly impact stability, load capacity, and installation requirements.

Feature | Two-Post Car Stacker | Four-Post Car Stacker |

Lifting Mechanism | Hydraulic Cylinder with Chain Drive | Hydraulic Cylinder with Steel Wire Rope |

Number of Posts | 2 Vertical Posts | 4 Vertical Posts |

Platform Support | Suspended (embossed metal plate) | Wheel-supported Runway Plates |

Load Capacity | 2000–3200 kg | 3000–5000 kg |

Installation Precision | High — requires exact post alignment | More tolerant due to four-point support |

Maintenance Needs | Regular lubrication and tension adjustment of chains | Periodic inspection of steel wire ropes |

Explanation

Two-post car lift operates via hydraulic cylinders and chains, lifting vehicles onto a suspended platform—think space-saving design for tighter garages. The platforms are typically constructed from embossed galvanized steel, so they’re tough enough for daily use. The catch? You’ve got to be precise with installation and stay on top of maintenance; otherwise, things can go sideways fast when it comes to safety or keeping everything level.

Four-post car lift takes a different approach, relying on steel wire ropes to distribute the vehicle’s weight across four posts and a solid runway platform that supports the wheels. This setup offers serious lateral stability—no wobble, no drama—so it’s a go-to choice for heavier vehicles, frequent lifting, and commercial shop environments. If you’re dealing with trucks or constant use, four-post lifts have the durability and stability you need.

Platform Design and Material Considerations

Platform Design and Materials in Two-Post vs Four-Post Car Lifts Configurations

Platform surface design impacts vehicle safety, operational functionality, and environmental durability.

Feature | Two-Post Platform: Embossed Plate | Four-Post Platform: Runway Plate |

Material | Hot-dip galvanized embossed steel | Perforated steel runways with central drip tray |

Surface Texture | Raised embossed patterns for anti-slip | Patterned with open cavities for drainage |

Accessory Integration | Moderate – compatible with some jacks | High – accommodates oil drip trays and hydraulic jacks |

Outdoor Suitability | Excellent with hot-dip galvanization | Good with epoxy zinc coating; iron drip trays available |

Explanation

Two-post platforms—often called embossed plates—are manufactured using a cold embossing process, which creates raised patterns on the surface. These patterns significantly enhance tire grip and safety, particularly under wet or slippery conditions. Earlier designs utilized corrugated, or “waving,” steel plates, but those have been mostly replaced due to inferior durability and slip resistance.

In contrast, four-post platforms utilize perforated runway plates with hollow centers. This design supports efficient drainage and allows convenient access for tools like oil drip trays or hydraulic jacks, making them a staple in automotive repair environments. For outdoor installations, applying hot-dip galvanization to two-post lifts is common practice, as it provides a protective layer against corrosion and helps extend the service life of the equipment in harsh environmental conditions.

Safety Mechanisms and Compliance

Safety Standards and Compliance in Hydraulic Two-Post and Four-Post Car Lifts

Both stacker types incorporate multi-layered safety features to comply with international standards.

Safety Feature | Two-Post Stackers | Four-Post Stackers |

Dual Safety Locking | Mechanical & Hydraulic | Mechanical & Hydraulic |

Emergency Stop Mechanism | Yes | Yes |

Overload Protection | Yes | Yes |

Lock Release | Standard | Optional |

Remote Control | Optional | Optional |

Explanation

When it comes to automated or semi-automated parking systems, safety isn’t negotiable—it’s the foundation. Both two-post and four-post car stackers are engineered to comply with rigorous standards like ANSI/ALI ALCTV and ISO for mechanical lifts. These systems incorporate dual locking mechanisms, mechanical and hydraulic, to ensure redundancy in case one fails. Emergency stop buttons are standard, allowing for immediate shutdown if something goes sideways. Overload protection is built in as well, so the equipment won’t operate outside its safe limits. All in all, these features work together to make sure the lifts function safely in actual, everyday use—not just in controlled environments.

Read the insight of How the Dual Safety Locking System Transforms Four-Post Car Lifts from Functional to Fail-Safe

User Experience and Parking Efficiency

Parking Efficiency and Usability: Two Post vs Four Post Car Lift Applications

User interface and parking ergonomics differ notably between two-post and four-post stackers.

Aspect | Two-Post System | Four-Post System |

Vehicle Access | Unobstructed front access | Posts at vehicle sides may obstruct |

Parking Maneuvering | Easier, better visibility | Slightly more complex due to posts |

Noise & Vibration | Moderate noise from chains | Generally quieter operation |

Suitability for Outdoor Use | Superior with hot-dip galvanized coating | Good with epoxy coatings |

Explanation

Two-post car lifts use side arms to support vehicles, keeping the center area clear so you can drive in without dodging posts or supports. It’s efficient, but you’ve got to map out your space—these lifts demand precise clearance and balanced placement, or things get sketchy fast.

Four-post car lifts, on the other hand, support the car on runways. You just drive on, no guessing games. The trade-off? Those four big posts can restrict movement, especially if your bay isn’t exactly generous on space. And don’t overlook the practical stuff: operating noise, how well the lift holds up over time, and whether it’s better suited for indoor or outdoor use. All these factors play a role in choosing the right lift for your setup.

Global Market Adoption and Use Cases

Global Adoption and Use Cases of Two-Post vs Four-Post Car Lift for Mechanics and Urban Parking

Region | Preferred Stackers | Typical Applications |

North America | Four-Post | Automotive repair shops, storage facilities |

Europe | Two-Post | Urban parking, valet systems |

Southeast Asia | Two-Post | Residential complexes, compact lots |

Middle East | Both | Luxury parking, mixed-use developments |

Australia/New Zealand | Four-Post | Home garages, commercial parking |

China & Korea | Mixed | Service centers (4-post), residential (2-post) |

Explanation

Regional lift preferences? It’s all about infrastructure, vehicle types, and what makes sense economically. Take North America: four-post lifts dominate because they’re built for heavier vehicles and integrate seamlessly into most service facilities. Over in Europe and Asia, space is a premium, so two-post lifts are the standard—they’re compact, cost-effective, and make efficient use of limited floor space. The Middle East? It’s a hybrid situation. You’ll see both types, depending on whether the facility caters to high-end vehicles or general service. At the end of the day, the real trick is picking equipment that aligns with local demand and operational realities, not just technical specs on paper. That’s how you get a setup that actually works in practice.

Economic Impact and ROI Analysis

ROI and Cost Analysis: Two-Post vs Four-Post Car Lift Investments

Parameter | Two-Post Car Stackers | Four-Post Car Stackers |

Initial Investment | Optimized cantilevered design and chain-driven mechanics deliver high performance at a cost-effective price point. | Lower upfront cost due to simpler structure and installation |

Operational Efficiency | High space utilization | Enhanced service revenue potential |

Maintenance Costs | Moderate (chain tension, lubrication) | Moderate to high (wire ropes inspection) |

Typical Payback Period | 6–18 months | 12–36 months |

Revenue Streams | Increased parking capacity | Parking + service facility income |

Explanation

Two-post car lifts are all about saving space—they’re compact, efficient, and perfect for valet setups, residential buildings, or mixed-use parking projects. On the flip side, four-post car lifts usually cost less upfront and are simpler to install, making them a solid, economical pick for businesses like auto shops or residential garages. Plus, they can pull double duty as both parking and maintenance platforms. Whether you go with a hydraulic two-post car lift or a hydraulic four-post car lift, your ROI really comes down to how you plan to use it, the maintenance setup, and your revenue strategy. Picking the system that fits your long-term operational goals is the best way to make that investment pay off.

From Blueprints to Reality

From Planning to Implementation: Integrating Hydraulic Two Post and Four Post Car Lifts in Design

Seeing the difference between two-post and four-post car lifts in action makes it much easier to understand how they work. The gallery below gives a real-world look at how these lifts fit into different architectural setups and day-to-day operations—turning parking headaches into smooth, efficient solutions.

Conclusion

Choosing Between Two Post vs Four Post Car Lift for Parking and Workshop Design

Here’s the techy lowdown. Two-post stackers? They’re compact, budget-friendly, and super easy to install—think tight urban projects or valet parking where you don’t have room to waste. They do the job for standard vehicles and make the most out of minimal space, but don’t expect them to haul anything massive.

Four-post stackers, on the other hand, are built for heavier lifting. They’ve got more muscle, better stability, and come with extra safety features. That’s why you’ll spot them in commercial garages, industrial settings, or anywhere you need to park something bigger than your average sedan.

So, if you’re in planning or architecture, it’s all about matching the right system to your constraints: site dimensions, user needs, upkeep, and, obviously, budget. Properly integrated, both stacker types can seriously boost parking efficiency and long-term cost savings. It’s a matter of picking the right tool for the job—no hacks or shortcuts.