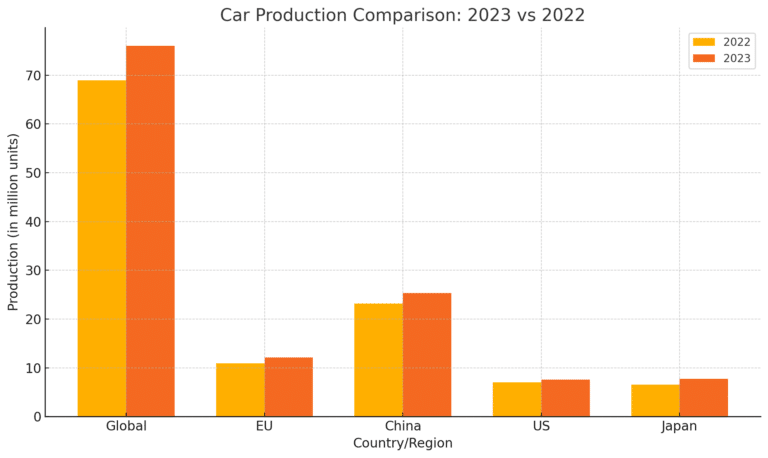

Due to a significant rise in the automotive industry, personal vehicle ownership has surged dramatically. In 2023, global car production reached 76 million units, marking a substantial 10.2% increase. The EU solidified its position as the second-largest car producer with 12.1 million units, growing over 11%. China produced over 25.3 million cars, representing more than a third of the global market with a 9% growth. The US and Japan also saw increases, producing 7.6 million and 7.7 million cars, respectively, with growth rates of 8.5% and 17.4%.

This surge in car production has intensified the demand for parking spaces, especially in urban and metropolitan areas where space is limited. As more vehicles crowd city streets, finding efficient and cost-effective parking solutions becomes essential. Furthermore, the global economy’s risk of recession in 2024 and following years further underscores the need for economical parking systems. Car stackers emerge as an ideal solution, offering a way to maximize parking spaces without significant capital investment.

This article will explore the fundamentals of car stackers, including their types, functionality, installation, maintenance, and cost-saving benefits. Additionally, it will compare hydraulic and motor-driven systems to help you choose the best option for your needs. By understanding these aspects, property owners and developers can make informed decisions to address parking challenges efficiently and economically.

A car stacker, also known as a parking stacker, a car storage lift or a simple parking lift. It’s a lifting machine that allows you to park multiple cars vertically in one car space. By this way, end users can have additional vehicle storage and multiple car parking spots in a limited space.

This stacker parking and car storage solution is becoming increasingly popular in urban areas due to the high traffic and limited living space. As many people struggle to find adequate parking, car stackers offer a practical remedy by maximizing vertical space and reducing congestion. These systems are now commonly found in luxury homes, high-rise apartments, common office building, valet parking facilities, professional auto repair shops, and new car showrooms. Car stackers provide an efficient and effective solution to modern parking challenges, making them a valuable asset in densely populated cities.

A car stacker operates on a straightforward principle: vehicles are parked on a lift platform, which then raises or lowers to create space for additional cars. The system can have up to four platforms stacked together, allowing for a maximum of five vehicles to be parked in the same footprint (four on platforms and one on the ground). Most car stackers use hydraulic systems for their cost efficiency and greater lifting capacity, although motor-driven systems are also used in some applications.

The primary goal of a car stacker is to save space by storing vehicles vertically. These machines can lift single or multiple vehicles simultaneously and position them parallel to the ground. By optimizing vertical space, car stackers provide an efficient solution for parking multiple vehicles in areas with limited space.

As the name suggests, a two-post car lift uses two columns to support and lift vehicles. One of the main advantages of this type of lift is its open-front design, which provides a better parking experience. Drivers can easily park and exit without any obstructions. The sharing post design of the two-post lift requires less space compared to four-post lifts, making it ideal for shops with limited room and small garages.

Typically, two-post lifts are designed for double stacking due to weight limitations. However, SolidParking has introduced innovative designs that support three-car parking with two posts, TTS-3. Also, SolidParking offers various models to suit different scenarios, such as the TP-320, TP-270, TP-270H, TP-230H, and TP-200, with lifting capacities ranging from 2000 KG to 3200 KG. Among them, the TP-200 model is specifically designed for low-ceiling areas, making it a versatile option for basement parking.

This efficient design ensures that the two-post car lift remains a user-friendly and space-saving solution for both residential and commercial settings.

4 post car lifts utilize four columns for structural support, allowing easy loading and positioning of much heavier vehicles. Their design ensures safe and reliable storage on multiple levels, unlike the 2-post lifts limited to 2 levels.

4 post lifts can serve as car storage lifts. Regular double stacker 4-post lifts are commonly found in home garages, useful for both parking and car repairs. Multilevel parking lifts like the MPS and FP-360X are ideal for car storage or valet parking solutions. In United States, the MPS-4 is frequently used in public parking lots as the land is a scarce resource in urban cities. The picture below shows a mechanical parking garage in 92 Livingston St. Manhattan, New York.

Examples of four-post car lifts from SolidParking include the MPS, FP-360, and FP-360X, with lifting capacities ranging from 3000 KG to 3600 KG. The typical parking width and height are 2100 mm and 1800 mm, respectively.

4-post 2 car lifts can be mobile, while 2-post car lifts need to be anchored to the ground for safety and stability. 3-car lifts and 4-car lifts are designed to provide three or four levels of vehicle storage, significantly boosting space utilization. These lifts are more stable and safer for long-term use compared to two-post lifts.

Pit parking lifts or Inground parking system, unlike conventional stacker parking lifts, store vehicles below ground level. These semi-automated systems allow users to park and retrieve their vehicles independently, without the need to move other cars. Pit parking lifts typically use hydraulic systems or high-power electric motors and can have two or four columns to support the load. They are popular in personal homes and residential parking lots.

SolidParking offers product lines such as CPS, IPS, and PTP, with load capacities ranging from 2000 KG to 3000 KG. The parking width and height can be customized to fit the pits. The speed of these inground lifts depends on the specifications of the cylinders and power stations chosen by customers. The control systems can be either relay-based IC or PLC-controlled.

Car stackers are an excellent choice for several compelling reasons. These systems simplify parking, enhance safety, and offer cost-effective, versatile solutions for both residential and commercial applications. Here’s why you should consider a parking stacker:

Car stackers are built to meet CE safety standards, ensuring complete safety and reliability. The sturdy structure guarantees system stability, while automated safety locks prevent sudden system falls. Sensors in every system ensure that any incorrect commands do not affect the overall operation, making car stackers a long-standing safe and reliable option.

Parking stackers offer significant cost savings. They eliminate the need for oversized garages, reducing construction costs. Their simple design makes them more affordable than semi-automated or fully automated parking systems. In addition to lower installation costs, maintenance is also cheaper and straightforward, saving money in the long run.

Many homes and apartment buildings have limited garage space. Car stackers provide an efficient solution by allowing multiple vehicles to be parked in the same footprint, freeing up additional space. This eliminates the need for renting extra parking spaces, providing convenient and secure storage for multiple vehicles.

Car stackers are designed for easy maintenance. With simple mechanisms, routine checks involve basic tasks such as inspecting hydraulic oil levels for hydraulic systems or checking wiring for electric systems. This straightforward maintenance ensures the longevity and reliability of the system without requiring complex procedures.

Beyond car parking, car stackers serve various purposes. Four-post car lifts can double as garage storage lifts for sundries or even as alternative solutions for boat docking. They can be customized for different payloads and lifting heights, making them suitable for diverse needs in residential, commercial, and industrial settings.

Operating a car stacker is straightforward, typically involving a deadman safety key switch or remote controller. This ease of use ensures that anyone can operate the system without extensive training, making it convenient for everyday use.

The majority of parking stackers use hydraulic drive over motor drive. There are several reasons we have made this choice.

(1)The car lifts can have a larger loading capacity by using a hydraulic system.

The hydraulic transmission uses the pressure of the hydraulic oil to transmit force. The pumps can obtain high pressure.

(2) sizeable power-to-weight ratio

The power-to-weight ratio is the ratio of the output power to its weight. For example, the importance of the hydraulic pump on the aircraft is only 0.209kg per KW of power, while the weight of the motor will reach 2kg per KW. Because the power packs are usually mounted on the lifts, it requires as little weight as possible.

(3) Easy to do the reciprocating movement.

Car stackers only move vertically. The hydraulic drive is designed to do reciprocating movement, and the motor must be through the gears, chains, and racks to turn the rotary motion into a linear reciprocating movement.

(4) The movement of hydraulic is more smooth and stable

Because the hydraulic fluid can be controlled evenly at minimal flow rates, the speed of motion of the lift can be very soft.

(5) Easy to prevent overload

The pressure valve in a hydraulic transmission setting can be used to control the system’s pressure and prevent overload and accidents. A pressure gauge can also be installed in the system to monitor load size and working conditions.

(6) Components are lubricated automatically, resulting in long service life.

Hydraulic oils create a lubricating effect on the hydraulic components. This allows the parts to have self-lubrication properties and extends their lifespan.

(7) The temperature of the surroundings impacts the parking system’s performance.

Because of the nature of the oils, the environmental temperature should not be either too high or too low. For the motor type, the user should not be worried about it.

(8) The noise of the motor type is lower than the hydraulic pump in general. The motor drive should be considered if the environments are very noise sensitive.

A typical parking stacker consists of three major parts: primary structure, power system, and control system.

In this section, we will discuss the retail market prices for car stackers. Note that wholesale or factory prices are not included here.

An average two-post car parking lift weighs around 1,000 kg. In the United States, the retail market prices for a single unit range between $4,500 and $9,000.

The retail price for a regular four-post car lift typically ranges from $2,800 to $5,500.

For lifts designed to accommodate three or four cars, prices generally start at $6,000. The cost can vary based on design, lifting capacity, and lifting height.

Installing a conventional two-post lift usually requires 2 labors a full day, while a four-post lift installation typically takes half a day with two skilled labors.

Spare parts for maintenance can range from $17 to $350, depending on the component.

Yes, car stackers are suitable for residential use, especially for a household has more than one car. They provide efficient parking solutions for apartments, condominiums, and private homes.

Car stackers are designed with multiple safety features such as sensors, safety locks, and emergency stop buttons to ensure safe operation. Regular maintenance and inspections further enhance safety.

The cost of a car stacker varies based on the type, size, and complexity of the system. Simple models may cost less than USD2,000 per unit, while advanced, automated systems can cost several hundred thousand dollars per parking pallet. For detailed pricing, you need to contact SolidParking team.

Car stackers require regular maintenance, including inspections, lubrication of moving parts, checking hydraulic fluids, and testing safety mechanisms. Maintenance schedules depend on the models and usage frequency.

A well-maintained car stacker can last between 15 to 30 years, depending on usage and maintenance. Regular servicing and timely repairs can extend its lifespan.

Yes, car stackers can be customized to fit specific space requirements and aesthetic preferences. Solidparking engineers can design systems to meet unique needs, including size, capacity, and functionality.

The weight capacity of a car stacker varies by model but typically ranges from 6,000 to 9,000 pounds per platform. It is important to choose a system that matches the weight of the vehicles to be parked.

Yes, modern car stackers are designed to be energy efficient, using advanced hydraulic or electric systems that consume minimal power. Some systems also include energy-saving features like standby modes.

Car stackers are designed to maximize space efficiency and can significantly increase parking capacity in limited areas. They require less ground space compared to traditional parking methods. Also there are several models with sharing post design which compact the space furthermore.

Yes, car stackers can be installed both indoors and outdoors. Outdoor installations require weather-resistant materials and additional outdoor solution package for protection against the elements.

Yes, car stackers have height restrictions based on the design and type of system. It is important to check the specifications to ensure vehicles fit within the allowable height range.

Yes, electric vehicles can be parked in car stackers. Some systems can be equipped with charging stations to accommodate electric vehicles while they are parked.

Car stackers are controlled using either manual keypads or remote controls.

Car stackers in commercial buildings offer several benefits, including increased parking capacity, efficient use of space, improved security, and enhanced property value. They also provide a convenient and economical solution for employees and customers.

Yes, car stackers can be relocated if necessary. However, the process requires professional disassembly, transportation, and reinstallation.

Car stackers are environmentally friendly as they reduce the need for large parking lots, helping to preserve green spaces. They also support urban densification, reducing vehicle emissions and promoting public transportation use.

The need for permits depends on local regulations and the scope of the installation. It is important to check with local authorities and follow all necessary procedures for installation.

The Double Car Lift TP-270 is used for parking and storing cars on the ground on top of the other. The system is built to lift a platform-mounted vehicle into the air and lock it there so that a different car may be parked in the space beneath the platform. Parking one automobile on top of another requires a minimum ceiling height of 3.5 meters.

The platform is made of solid unperforated waving plates with integral bent curbs on each side, while the plates are made of galvanized steel. This steel plate has inverted U-Bends fastened to the underside at certain intervals to provide lateral reinforcement. The entire assembly of the storage lift, which weighs 1100 kg, is pre-fabricated and can be put together on-site.

The hydraulic cylinder rods that power the stacker are chrome-plated to avoid rusting. A pump and motor are part of the hydraulic system that raises and lowers the platform, and a 24-volt relay and valve set manage them. The hydraulic circuit maintains a consistent fall rate regardless of the loading situation. In an electrical outage, a manually driven emergency pump is available to enable platform lowering without electrical power.

The car lift cannot be operated with a load of more than 2.7 tons due to a pressure-compensated hydraulic overload prevention circuit. The device has a planar laser system and a safety locking system. Whether the hydraulic or electric operation is used, the “posi-lock” double lock-down system maintains the automobile’s whole weight on the platform in the locked position. Each lift has a controller with a CE standard key switch, which adds another layer of security for self-parking applications.