Elevator Parking Garage S-VTS car transportation and storage

Why Elevator Car Garages Are the Future of Parking

In cities where space is scarce, traditional ramps waste valuable square footage. That’s why the elevator car garage—sometimes called an elevator parking garage or car garage elevator—is becoming a preferred choice for architects and developers.

Instead of ramps, cars move vertically through hydraulic lifts designed for safety and efficiency. SolidParking’s Vehicle Transportation System (VTS) has been engineered with different models, from compact two-post lifts to heavy-duty scissor platforms, to meet the diverse needs of modern parking.

Insights into parking innovations, urban planning, and vehicle lift systems: International Parking & Mobility Institute (IPMI)

Elevator Parking Garage Advantage 1: Heavy Load Capacity

Unlike standard lifts, the elevator parking garage supports up to 10 tons per platform. This allows it to move not only cars but also SUVs, pickup trucks, and light commercial vehicles.

For car dealerships, this means transporting entire fleets with confidence. For homeowners, it ensures a future-proof solution that won’t be limited to small sedans.

Elevator Car Garage Advantage 2: Multi-Car Stacking

The elevator car garage is not just about lifting one car. Scissor-type VTS models allow stacking two or three cars per platform, multiplying storage without expanding the footprint.

In luxury villas, this means hiding multiple vehicles underground while preserving a clean, landscaped exterior. For urban developments, this vertical strategy maximizes rentable space.

Other Multi-Car Stackers:

Car Garage Elevator Advantage 3: Advanced Safety Systems

Safety is the foundation of every car garage elevator design. Built-in systems include:

· Anti-fall locks for scissor and post lifts.

· Dual-chain protection in four-post systems.

· Explosion-proof valves and overload protection.

· Photocell sensors and limit switches for real-time monitoring.These redundant layers of protection meet EU safety standards, making the car garage elevator a reliable choice for both residential and commercial use.

👉 Further Reading of Solid Parking’s Safety Locking system: How the Dual Safety Locking System Transforms Four-Post Car Lifts from Functional to Fail-Safe

Elevator Parking Garage Advantage 4: Cost Efficiency

One of the biggest strengths of an elevator parking garage is its cost structure. Hydraulic-driven lifts use simpler components than passenger elevators, lowering both installation and maintenance costs.

Developers benefit from a shallower pit depth—often as little as 500 mm—which cuts excavation expenses. Over the system’s lifespan, maintenance relies on standard hydraulic servicing, not costly elevator specialists.

Elevator Car Garage Advantage 5: Space Optimization

Every square meter matters in urban real estate. The elevator car garage eliminates the need for ramps, freeing up large areas for more profitable uses.

For luxury homes, that could mean turning driveway space into gardens or entertainment areas. For commercial projects, it translates into more leasable units, boosting revenue potential.

Car Garage Elevator Advantage 6: Flexible Applications

The car garage elevator is adaptable across industries:

· Car dealerships & showrooms: Seamless movement of display cars across floors.

· Residential villas: Hidden underground parking for modern design aesthetics.

· Automated parking garages: Integration with AGVs and robotics for smart urban parking.

This flexibility ensures that the car garage elevator works equally well in private, commercial, and industrial projects.

Elevator Parking Garage Advantage 7: Scalable Models

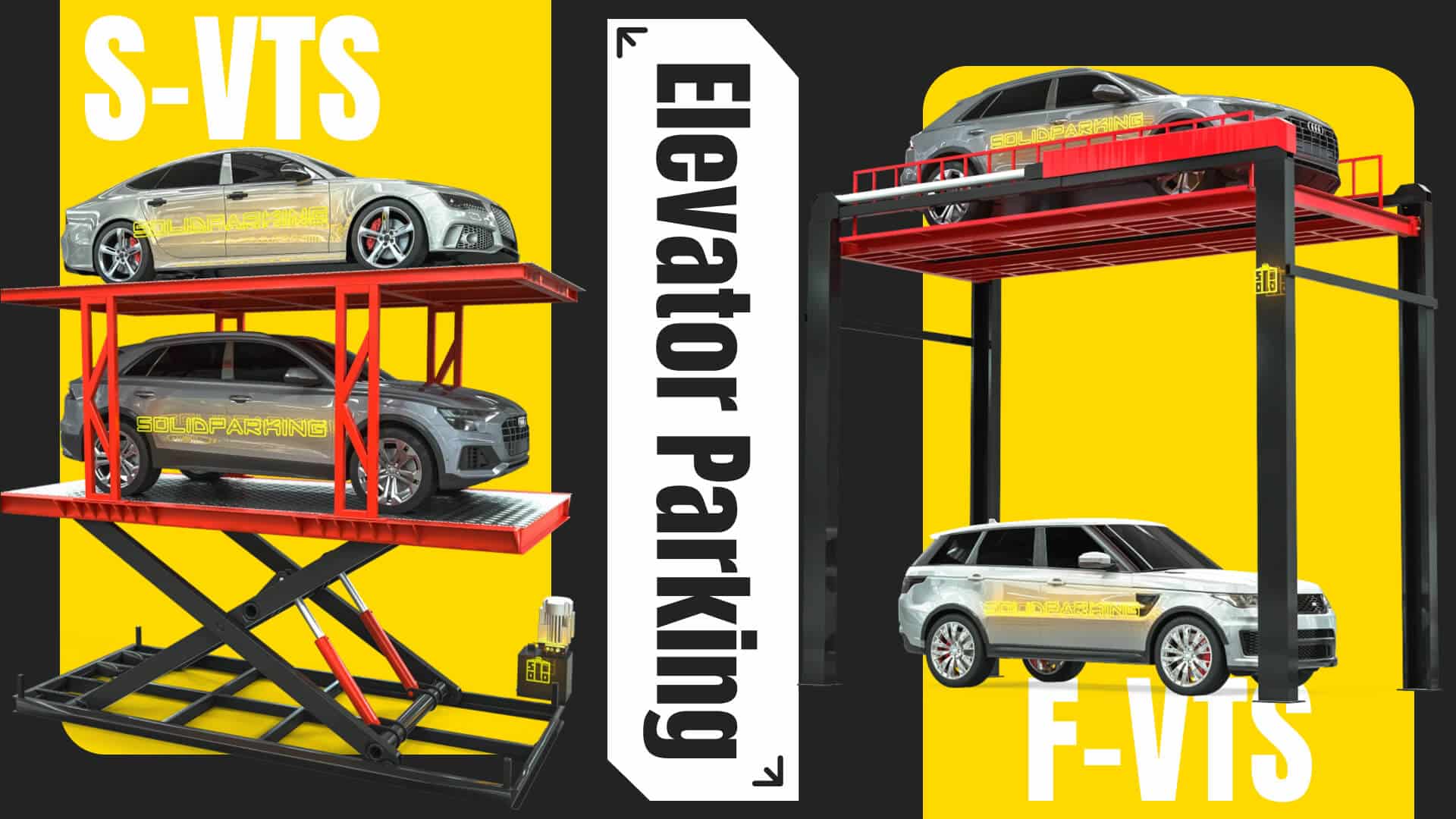

Not every project has the same parking demands. SolidParking provides scalable options:

· S-VTS (Scissor Type) → Heavy-duty, up to 20,000 kg, customizable height.

· F-VTS (Four-Post Type) → ≤ 5,000 kg, cost-efficient for villas.

· TP-VTS (Two-Post Type) → Compact footprint, ≤ 3,500 kg.

· Shaft-Type VTS → High-rise, enclosed elevator parking garage systems.

This scalability allows architects to specify the right elevator parking garage for each project—from a small residential garage to a multi-level commercial tower.

| Specification | S-VTS (Scissor Type) | F-VTS (Four-Post Type) |

|---|---|---|

| Drive System | Hydraulic scissor lift | Hydraulic four-post lift |

| Lifting Capacity | 3,000 kg standard (customizable 500–20,000 kg) | ≤ 5,000 kg |

| Lifting Height | 2,100 mm (up to 10 m customizable) | 2,200 mm (customizable) |

| Vehicle Dimensions | L: 5,000 mm / W: 2,000 mm | L: 5,000 mm / W: 2,500 mm |

| Lifting Speed | 3.5 m/min | 4 m/min |

| Platform Options | 1–3 platforms (multi-car stacking possible) | Single platform only |

| Control System | Relay control | Integrated modules for simple wiring |

| Safety Features | Anti-fall locks, explosion-proof valves, limit switches | Dual chain protection, photocell sensor, limit switches |

| Installation | Pre-assembled; crane needed for placement | Posts assembled on-site, easier relocation |

| Best Use Cases | Basements, underground garages, commercial lots, hidden stack parking | Residential garages, villas, showrooms, cost-focused projects |

Elevator Car Garage Advantage 8: Easy Installation & Relocation

Construction timelines are tight. The elevator car garage is designed for efficient installation:

· Scissor-Type → Pre-assembled, lowered into place with a crane.

· Four-Post Type → Assembled on-site, easier to dismantle and relocate later.

This flexibility makes the elevator car garage attractive for both permanent builds and semi-permanent projects where relocation might be required.

Elevator Parking Garage Installation Steps

Installing an elevator parking garage system (VTS) requires professional handling to ensure safety, precision, and long-term performance. While exact procedures vary by model, the general process includes:

1. Site Preparation

– Review architectural drawings and determine lift placement.

– Excavate according to platform size and pit depth.

– Prepare drainage if necessary for underground garages.

2. Foundation Work

– Install U-shaped steel frames and reinforcement.

– Pour C30-grade concrete for strength and stability.

– Allow 7–28 days curing time to achieve structural integrity.

3. Anchor Installation

– Drill M30*1 anchor bolt holes.

– Reserve expansion pipes for long-term maintenance access.

4. Lift Placement

– Scissor Type (S-VTS): Use a crane to lower the pre-assembled lift into the pit, then secure with anchor bolts.

– Four-Post Type (F-VTS): Assemble posts on-site, then install the platform on top.

5. Hydraulic & Electrical System Setup

– Connect hydraulic cylinders, oil pipelines, and explosion-proof safety valves.

– Wire the integrated control box (24V control power).

– Configure limit switches and photocell sensors for safety.

6. System Calibration & Testing

– Conduct no-load and full-load trials.

– Check lifting speed, noise levels, and hydraulic pressure balance.

– Perform safety tests on anti-fall locks, overload valves, and emergency stop functions.

7. Final Handover & Training

– Provide operator training for end users.

– Deliver a maintenance manual covering inspections, lubrication, and troubleshooting.

By following these steps, contractors ensure the elevator parking garage system runs smoothly, safely, and with minimal downtime after installation.

Elevator Parking Garage Advantage 9: Market-Proven Reliability

The elevator parking garage is not a new concept—it’s already deployed in luxury homes, dealerships, and commercial garages worldwide.

SolidParking sits between premium German manufacturers (Klaus, Wohr, Nussbaum) and budget Chinese suppliers. The company’s positioning offers European-standard safety combined with cost efficiency, making the elevator car garage a competitive choice in global markets.

Regional Market Outlook for Elevator Car Garages

North America

· Growing demand for residential car garage elevators in luxury homes.

· Developers in New York, LA, and Miami rely on elevator parking garages to overcome zoning and land costs.

Europe

· Heritage cities like Paris and London adopt elevator car garages to reduce ramp footprints.

· Preference for scissor and shaft-type systems in mixed-use projects.

Regulatory guidance for elevator safety standards, relevant for elevator car garages in EU markets: European Lift Directive (ELD)

Asia-Pacific

· Fastest adoption of elevator parking garages in Tokyo, Seoul, and Shanghai.

· Government-supported rollouts of automated parking systems with VTS integration.

Middle East

· Car garage elevators installed as lifestyle features in villas across Dubai and Doha.

· Luxury malls and showrooms use elevator car garages as prestige solutions.

Conclusion: Why Elevator Car Garage Systems Are Future-Proof

The elevator car garage, also known as an elevator parking garage or car garage elevator, has proven to be more than just an engineering innovation—it’s a strategic tool for property development.

By offering heavy load capacity, space optimization, safety, cost efficiency, and global scalability, this technology meets the needs of modern urban living.

For architects, it unlocks design flexibility. For developers, it maximizes ROI. And for homeowners, it provides safe, space-saving, and future-ready parking.

As cities grow upward and land costs rise, the elevator car garage stands out as one of the smartest investments in real estate development.