7 Powerful Reasons Why the SSP Chess Parking System Outperforms Traditional Automated Parking

Urban Parking: The Business Realities

Let’s be blunt: parking in the city is a logistical headache and a financial drain. Traditional parking garages chew up premium real estate with inefficient ramps and winding drive aisles, while outdated “automated” systems often fall short—think slow vehicle retrieval, questionable safety, or limited car compatibility. It’s not a winning combination for any operator aiming to maximize profits per square foot.

Now, SSP Chess Parking (Super Square Parking, for those invested in acronyms) from SolidParking resets the game entirely. This platform operates cars like chess pieces, sliding them over a grid of motorized pallets. Forget about wasted space for aisles—SSP delivers an eye-popping 85–90% space efficiency, ultra-fast retrieval, and a safety profile built for confidence, not stress.

Why does this matter for your business? There are seven compelling competitive advantages that push SSP ahead of shuttle and palletless automated systems. In a market where returns on real estate and user experience define success, the SSP Chess Parking System stands out as the smart move for forward-thinking organizations. Here’s why it’s leading the charge into the future of automated parking.

More Reading: The Evolution of Urban Mobility: Fully Automated Parking Systems

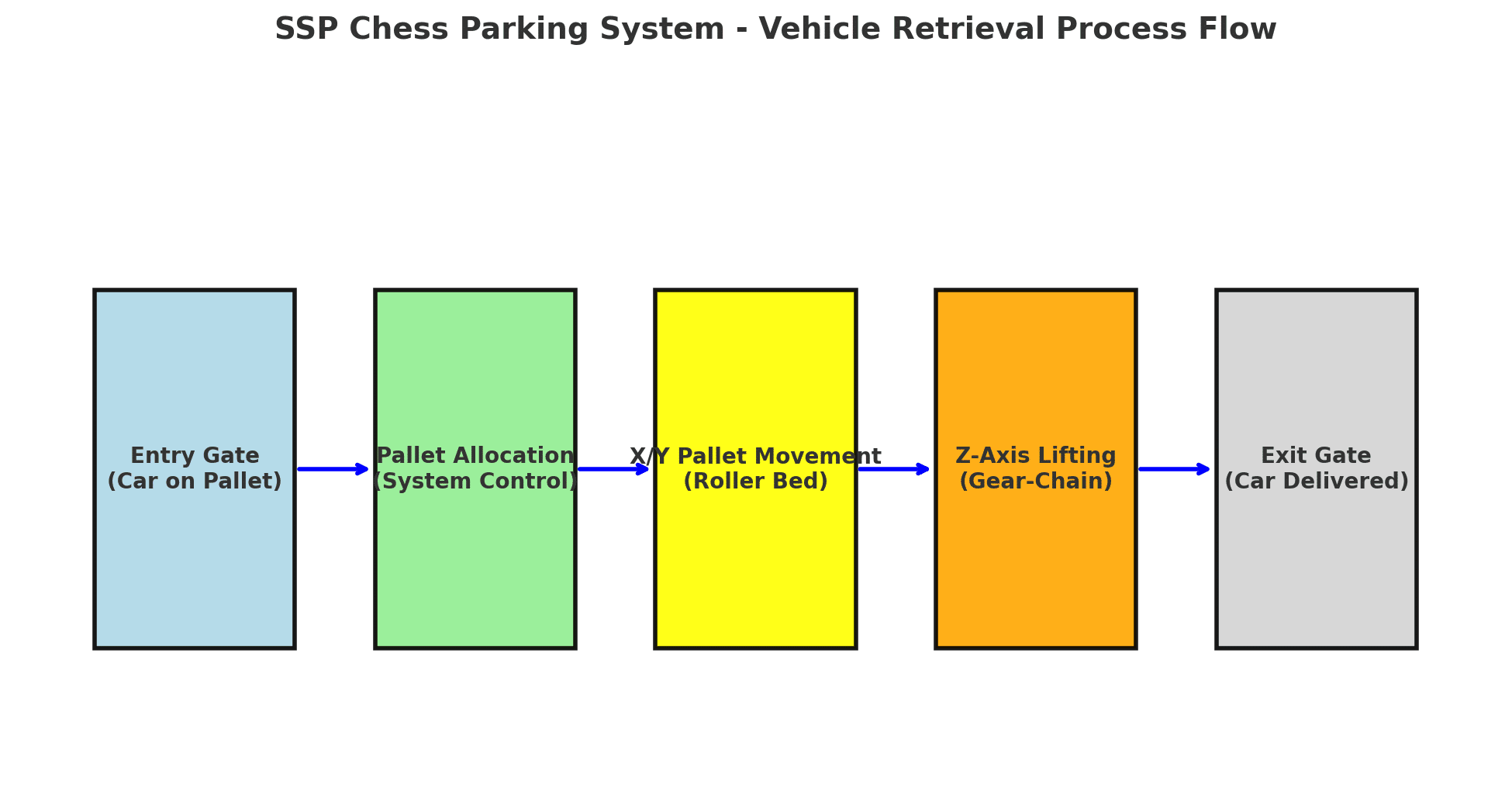

It breaks down into five engineering stages:

Entry Gate → Car rolls onto pallet, authenticated via IC card/touchscreen.

Pallet Allocation → PLC (Programmable Logic Controller) assigns optimal bay/route.

X/Y Pallet Movement → Omni-directional roller bed moves pallet at 30 m/min.

Z-Axis Lifting → Gear-chain lift powered by a 15 kW motor raises/lowers car.

Exit Gate → Car is delivered back to the driver.

1. Unmatched Space Efficiency with the Chess Parking System (85–90% Floor Utilization)

Traditional shuttle systems sacrifice space for carrier aisles. SSP doesn’t. Its roller bed mechanism enables omni-directional movement, so pallets slide in any direction without dedicated tracks.

📌 Jargon Explained

· Omni-directional movement → Pallets can move in both X (horizontal) and Y (longitudinal) axes, like chess pieces on a board.

· Floor-plate utilization ratio → The percentage of the garage floor actually used for cars. SSP achieves 85–90%, compared to ~70% in shuttle solutions.

👉 Why it matters: Developers maximize every square meter, lowering excavation costs and improving ROI.

2. Faster Vehicle Retrieval (90–120 Seconds)

Nobody wants to wait five minutes for their car. SSP reduces retrieval time to 90–120 seconds per vehicle, even in mid-size complexes with 100+ bays.

· Horizontal speed: 30 m/min via roller beds

· Vertical speed: 8–10 m/min via chain-driven lifts

· Throughput: 25–35 cars/hour per module

📌 Jargon Explained

Throughput → Number of cars a system can park or retrieve per hour. SSP outpaces palletless systems and rivals shuttle systems without losing space efficiency.

👉 Why it matters: High throughput keeps traffic flowing at office towers, shopping centers, and residential complexes during peak hours.

3. Robust Multi-Layer Safety Systems Built

Parking safety is not optional—it’s essential. SSP integrates redundant mechanical and electronic safeguards:

· Light curtains stop pallets instantly if beams are broken.

· Car presence sensors confirm occupancy before movement.

· Height detection (LIDAR/ultrasonic) prevents SUVs from entering low bays.

· Anti-fall arrestors mechanically lock pallets in case of chain failure.

· Overload relays guard against power surges.

📌 Jargon Explained

· Light curtain → A grid of invisible infrared beams that act as an electronic “safety fence.”

· Anti-fall arrestor → A fail-safe that catches a pallet if lifting chains snap.

👉 Why it matters: SSP not only prevents accidents but also builds operator confidence and compliance with ISO/EN safety codes.

4. SUV & EV Compatibility: A Future-Ready Chess Parking System Design

Unlike older systems optimized for sedans, SSP is designed for today’s heavier, taller vehicles—including electric vehicles (EVs) with larger battery packs.

· Max load: 2,500 kg per pallet

· Vehicle envelopes:

Sedans: ≤ L5300 × W1950 × H1550 mm

SUVs: ≤ L5300 × W1950 × H2050 mm

· Optional EV charging pallets: Seamless integration into daily use.

📌 Jargon Explained

Vehicle envelope → The maximum size and shape of a car the system can accept.

👉 Why it matters: SSP won’t become obsolete as EV adoption surges worldwide.

5. Smarter Automation and Control

Behind the smooth motion of SSP is its intelligent control stack:

· PLC (Programmable Logic Controller): Coordinates all pallet moves with millisecond precision.

· SCADA (Supervisory Control and Data Acquisition): Real-time monitoring for operators.

· HMI panels: Intuitive driver interface at entry gates.

· RFID/IC cards: Secure and fast authentication.

· Predictive maintenance: AI-based monitoring detects wear before failure.

📌 Jargon Explained

· SCADA → Industrial-grade monitoring system used in factories and power plants, now in parking.

· Predictive maintenance → Maintenance triggered by data patterns, not breakdowns.

👉 Why it matters: Lower downtime, lower service costs, and smoother user experience.

6. Modular, Scalable Architecture of the Chess Parking System

SSP is not one-size-fits-all. It’s modular, allowing architects and developers to customize height, length, and width.

· Works in residential towers, office complexes, and public garages.

· Scales from dozens to hundreds of bays.

· Compatible with BIM (Building Information Modeling) for early-stage design simulation.

📌 Jargon Explained

BIM integration → Architects can digitally “test” how SSP performs in their building before construction.

👉 Why it matters: Future-proof adaptability reduces risk for developers and ensures smooth integration with urban projects.

7. Why the Chess Parking System Outperforms Shuttle and Palletless Systems

Here’s how SSP stacks up against its rivals:

| Attribute | SSP Chess System | Shuttle/AGV Systems | Palletless Systems |

|---|---|---|---|

| Space Efficiency | 85–90% | 70–75% | 80–85% |

| Throughput | 25–35 cars/hr | 30–60 cars/hr | 20–30 cars/hr |

| Complexity | High (but modular) | Medium–High | Medium |

| Best Fit | Urban infill, mid-size projects | Airports, mega-garages | Low-ceiling projects |

👉 Why it matters: Shuttle systems may win on pure speed, but SSP offers the best balance of space efficiency, safety, and adaptability.

How SSP compares to other common system architectures

Below is a concise comparison of SSP-style chess/puzzle systems versus representative vendors/architectures in the automated-parking space.

| System / Vendor | Architecture type | Shuttle aisle required? | Pallet vs palletless | Throughput / Practical note | Typical strengths |

|---|---|---|---|---|---|

| SolidParking — SSP | Chess / motorized plate (pallet) | No | Pallet on roller beds (motorized) | High density, fast in/out for mixed bay layouts | Max usable floor area; modular; optional sensors. |

| ParkPlus / Rack & Rail / AGV | Rack & rail, AGV, fixed-rail shuttles | Yes (shuttle lanes / transfer paths) | Can be pallet or carrier-based | Proven for very large installations; flexible formats | Scales to hundreds/thousands; robotics & orchestration. |

| Westfalia | Palletless (vehicle handling without tray) & other automated types | Usually no for some palletless designs | Palletless (saves vertical space) | High throughput / ROI claims | Palletless saves cost & height; high space efficiency. |

| KLAUS Multiparking | Fully-automatic + mechanical stacking systems | Varies by model (some shuttle/transfer elements) | Pallet/palletless depending on product | Long-established tech partner with service network | Strong service/support global footprint. |

| Robotic Parking Systems (RPS) | Robotic shuttles & multi-robot orchestration | Often uses robotics + transfer aisles | Robotic carriers / pallet or palletless variants | Designed for very large scale, high automation | Emphasizes green / large-scale installations. |

Takeaway: SSP’s chess/pallet approach trades some mechanical simplicity for maximal floor utilization and fast in/out in tight footprints. Palletless systems (Westfalia) may save height and complexity but use a different handling strategy. Shuttle/AGV systems (ParkPlus, RPS) are often selected where extremely large capacity or particular operational workflows (centralized transfer points) are required.

Bonus: Industry Trends & News

· Market Growth: The automated parking sector is valued at ~$2.2B (2024) with double-digit CAGR.

· India & Middle East: New chess-style deployments in Hyderabad, Noida, and Dubai show global adoption.

· Sustainability: Compact excavation means lower embodied carbon compared to ramped garages.

FAQs

It’s an automated parking solution where vehicles move on motorized pallets like chess pieces across a grid.

With light curtains, anti-fall devices, and multi-sensor redundancy, it exceeds international safety standards.

Yes—vehicles up to 2,500 kg, including tall SUVs and EVs with charging options.

On average, 90–120 seconds per car.

Urban infill developments, mixed-use complexes, and high-density residential or commercial sites.

Conclusion: SSP as the Future-Ready Choice

The SSP Chess Parking System isn’t just another automated garage—it’s a technical evolution in how cities store cars. By combining space efficiency, rapid throughput, multi-redundant safety, EV readiness, and modular scalability, SSP outperforms shuttle and palletless rivals in real-world conditions.

As land costs rise and EVs dominate, SSP offers a future-proof, engineering-driven parking solution for developers, architects, and urban planners worldwide.

👉 : Want to compare SSP with our triple-stack FP-630 lift or Parksmart-ready solutions? Explore our full range of automated parking innovations.