Hydraulic Two Post Car Stacker: The Smarter Choice

Car Stackers Explained: What to Know Before You Buy

Table of Contents

Global Car Production Growth in 2024: Slowing But Still Climbing

Global car production continued its upward trend in 2024 — but at a much more moderate pace than the previous year.

According to preliminary data, global car output hit ~89 million units, marking a 3.7% increase over 2023’s output. That may seem modest compared to the 10% jump in 2023, but it still represents a steady climb as post-pandemic demand stabilized across a wide range of markets and vehicle categories.

Breaking it down:

-

China: still the world’s automotive powerhouse, producing 31.3M vehicles, up 3.7% YoY.

-

Europe (EU): much flatter growth at just 0.8%.

-

Japan: after a strong rebound in 2023, demand softened, and production dropped 7.5%.

Meanwhile, global light vehicle sales reached 15.9M, a modest 2.2% increase.

In short: production has surpassed pre-pandemic levels, but capacity and infrastructure — including parking — haven’t caught up yet.

🅿️ The Growing Parking Crunch in Urban Centers

More cars mean more strain on already overstretched parking resources.

By 2024, global vehicle ownership reached ~1.5 billion vehicles. And yet, in dense urban areas — where most of these vehicles are concentrated — parking space is increasingly scarce.

Take China: estimates show a national parking shortfall of nearly 80 million spaces, with major cities bearing the brunt. Residents face increasing congestion, wasted time searching for parking, and frustration.

This imbalance between growing demand and fixed supply has made space-efficient solutions critical for developers, operators, and municipalities.

Economic Realities: Why Cost-Efficient Parking Matters

The economic backdrop of 2024–2025 amplifies the need for smarter parking strategies.

Slower global growth, looming recession risks in some regions, and persistent inflation have forced developers and operators to cut costs wherever possible.

High land prices and construction costs make conventional multi-story or underground garages uneconomical, especially in premium urban areas.

Developers and operators are now turning to space-efficient solutions like stacker lifts.

These lifts can adapt to a wide range of urban settings and development needs, saving space and reducing costs.

Why Car Stackers Are Surging in Popularity

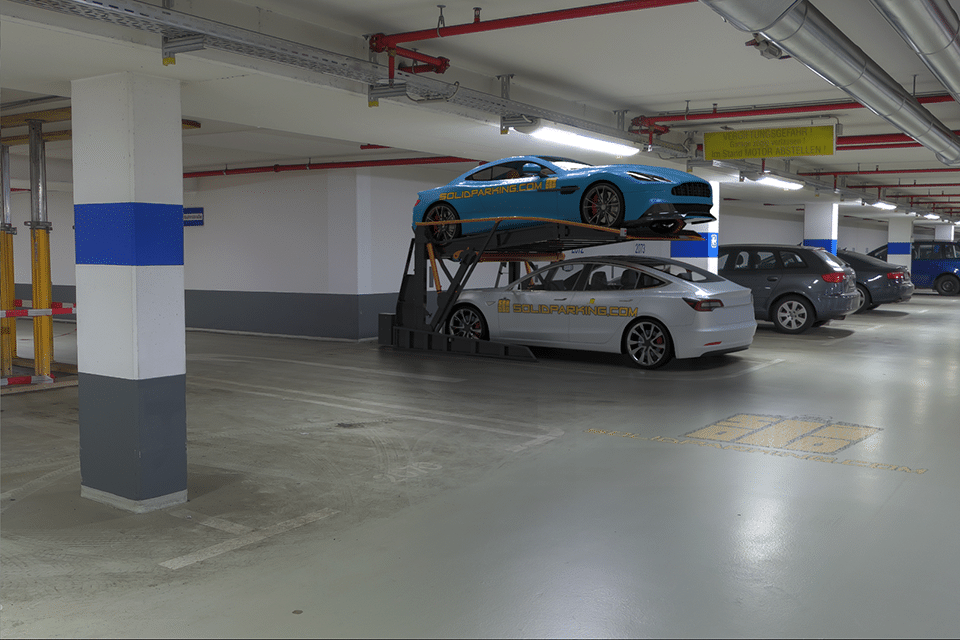

Car stackers — also known as parking stackers, car storage lifts, or simply parking lifts — are mechanical systems that park multiple cars vertically.

By maximizing vertical space, stackers allow 2–4 vehicles to be parked in the footprint of 1 — a game-changer in crowded cities.

They’re now widely used in:

✅ Luxury homes and townhouses

✅ High-rise apartments and condos

✅ Office buildings and commercial complexes

✅ Valet parking garages

✅ Auto repair shops and showrooms

Beyond space efficiency, stackers deliver:

Lower construction costs per parking space

Quick installation & flexibility

Lower maintenance vs. fully automated systems

For cities, developers, and businesses looking for smart, affordable solutions in 2025, stackers are an obvious choice.

How Does a Car Stacker Work?

The concept is simple: a platform lifts vehicles vertically, creating space underneath for more cars.

Most systems are powered by hydraulics, though motor-driven models are used in some noise-sensitive settings.

Basic configurations:

· 2 platforms (double stacker)

· 3 platforms (triple stacker)

· 4 platforms (quad stacker)

The most common stackers use hydraulic systems, offering higher capacity and smoother motion. Platforms remain level during lifting, and the system can be customized for different weights and heights.

Types of Car Stackers: Which One Do You Need?

🪜 Two-Post Car Parking Lifts

· Design: two columns with a shared post.

· Advantages: open front, easy access, smaller footprint.

· Best for: residential garages, shops with limited space.

· SolidParking models: TP-200, TP-230H, TP-270, TP-270H, TP-320 (2000–3200 kg capacities).

Notably, the TP-200 is engineered for low-ceiling basements, making it highly versatile.

🪜 Four-Post Car Lifts

· Design: Four columns, greater stability, heavier loads

· Advantages: Higher storage levels, long-term reliability

· Best for: Valet garages, commercial buildings, car showrooms

· Models: MPS, FP-360, FP-360X

· Extra capacity: 3-car & 4-car lifts for vertical storage of up to 4 vehicles

At SolidParking, every FP-360 installation starts with a careful check of all components. Making sure everything is on hand and in order sets the stage for a smooth process. By following each step correctly, our team ensures the lift goes together safely and efficiently. This also shows how SolidParking’s precision machining and manufacturing make the installation straightforward from the very beginning.

Unleash the Power of the Lift: Installation From Start to Finish!

🪜 Pit Parking Lifts / Inground Systems

· Design: vehicles are stored below ground level.

· Advantages: preserves above-ground aesthetics, fully independent access.

· Best for: luxury homes, high-end residential lots.

· SolidParking models: CPS, IPS, PTP (2000–3000 kg).

Why Choose Hydraulic Over Motor?

Hydraulic systems dominate stacker designs — and here’s why:

✅ Larger lifting capacity

✅ Smooth, stable motion

✅ Overload protection via pressure valves

✅ Automatically lubricated components

✅ Compact and lightweight

✅ Long service life

When to consider motor-driven systems?

In environments where noise is a top concern (like luxury residences), motor drives can be quieter.

Hydraulic type vs. Motor type

| Factor | Hydraulic Drive (Preferred) | Motor Drive |

|---|---|---|

| 1. Loading Capacity | Higher — can handle larger loads due to high-pressure hydraulic transmission. | Lower — more limited lifting capacity. |

| 2. Power-to-Weight Ratio | Excellent — compact and lightweight (e.g., 0.209kg per kW). Ideal for lifts with mounted power packs. | Poorer — heavier (about 2kg per kW). |

| 3. Motion Type | Naturally suited for vertical, reciprocating movement. | Requires gears, chains, and racks to convert rotary motion to linear. |

| 4. Motion Quality | Smooth and stable — even, controlled speed at minimal flow rates. | Can be less smooth due to mechanical transmission. |

| 5. Overload Protection | Easy — pressure valves and gauges control system pressure and prevent overload or accidents. | Less inherent overload control; requires additional design. |

| 6. Component Lubrication | Self-lubricated by hydraulic oil — longer service life. | No inherent lubrication — parts may wear faster. |

| 7. Temperature Sensitivity | Oil performance can degrade in extreme hot or cold environments. | Less sensitive to ambient temperature. |

| 8. Noise Level | Louder — hydraulic pumps generate more noise. | Quieter — recommended for noise-sensitive environments. |

📌 Key Takeaway:

✅ Hydraulic drives remain the standard for stackers thanks to their strength, smoothness, and reliability — but motor drives are a good alternative in low-load, noise-sensitive settings.

How Much Does a Stacker Cost?

How Much Does a Stacker Cost?

Retail prices:

· Two-post stacker: $2,200–$4,000/unit

· Four-post stacker: $1,700–$4,500/unit

· 3–4 parking stackers: starting at ~$6,000/unit

Installation & Maintenance

· Two-post: ~1 day, 2 workers

· Four-post: ~½ day, 2 workers

· Maintenance: Spare parts $17–$350

· Wholesale discounts: Contact SolidParking

Real-World Applications:

· Manhattan: MPS-4 stackers enabled tight lots to park dozens of cars

· Hong Kong & Singapore: TP-230H & TP-320 used in high-rises, meeting municipal parking minimums

Real-World Applications: SolidParking in Action

In Manhattan’s 92 Livingston St. mechanical garage, SolidParking’s MPS-4 stackers enabled a tight urban lot to accommodate dozens of cars, slashing construction time and costs.

Elsewhere, high-rise condos in Hong Kong and office buildings in Singapore have used the TP-230H and TP-320 models to maximize space and satisfy municipal parking minimums — all while preserving aesthetics and budget.

Why SolidParking?

For over a decade, SolidParking has combined engineering expertise and manufacturing excellence to deliver reliable, safe, and cost-effective stacker solutions worldwide.

All systems meet or exceed CE safety standards, with:

✅ Sturdy structures & safety locks

✅ Intelligent sensors & overload protection

✅ User-friendly controls & low maintenance

Whether it’s a compact two-post lift, the best 4 post auto lift, or a fully integrated pit system, SolidParking has the right model — and the experience — to make your project a success.

🚀 Take the Next Step

With parking demand rising and budgets tightening, stackers are the clear solution for 2025 and beyond.

Contact a SolidParking expert today to discuss your project.

Frequently Asked Questions (FAQ) About Car Stackers:

Yes, they are suitable for residential use, especially for a household has more than one car. They provide efficient parking solutions for apartments, condominiums, and private homes.

Car stackers are designed with multiple safety features such as sensors, safety locks, and emergency stop buttons to ensure safe operation. Regular maintenance and inspections further enhance safety.

The cost of a car stacker varies based on the type, size, and complexity of the system. Simple models may cost less than USD2,000 per unit, while advanced, automated systems can cost several hundred thousand dollars per parking pallet. For detailed pricing, you need to contact SolidParking team.

Most of the stackers require a regular maintenance, including inspections, lubrication of moving parts, checking hydraulic fluids, and testing safety mechanisms. Maintenance schedules depend on the models and usage frequency.

A well-maintained parking stacker can last between 15 to 30 years, depending on usage and maintenance. Regular servicing and timely repairs can extend its lifespan.

Yes, they can be customized to fit specific space requirements and aesthetic preferences. Solidparking engineers can design systems to meet unique needs, including size, capacity, and functionality.

The weight capacity of a car lift varies by model but typically ranges from 6,000 to 9,000 pounds per platform. It is important to choose a system that matches the weight of the vehicles to be parked.

Yes, modern car stackers are designed to be energy efficient, using advanced hydraulic or electric systems that consume minimal power. Some systems also include energy-saving features like standby modes.

These parking lifts are designed to maximize space efficiency and can significantly increase parking capacity in limited areas. They require less ground space compared to traditional parking methods. Also there are several models with sharing post design which compact the space furthermore.

Yes, they can be installed both indoors and outdoors. Outdoor installations require weather-resistant materials and additional outdoor solution package for protection against the elements.

Yes, they have height restrictions based on the design and type of system. It is important to check the specifications to ensure vehicles fit within the allowable height range.

Yes, electric vehicles can be parked in car stackers. Some systems can be equipped with charging stations to accommodate electric vehicles while they are parked.

Car stackers are controlled using either manual keypads or remote controls.

Car stackers in commercial buildings offer several benefits, including increased parking capacity, efficient use of space, improved security, and enhanced property value. They also provide a convenient and economical solution for employees and customers.

Yes, car stackers can be relocated if necessary. However, the process requires professional disassembly, transportation, and reinstallation.

Car stackers are environmentally friendly as they reduce the need for large parking lots, helping to preserve green spaces. They also support urban densification, reducing vehicle emissions and promoting public transportation use.

The need for permits depends on local regulations and the scope of the installation. It is important to check with local authorities and follow all necessary procedures for installation.

🔷 Spotlight: SolidParking TP-270 Double Car Lift

For projects that demand versatile, reliable, and space-efficient parking, the SolidParking TP-270 is a proven choice.

This double car stacker is designed to park and store two vehicles vertically — one above the other — in a single parking footprint. It’s ideal for residential and commercial applications where ceiling heights allow vertical stacking.

🚗 Key Features of the TP-270:

✅ Space-Saving Design

Allows two cars to be parked in one spot, with a minimum ceiling height of just 3.5 meters.

✅ Heavy-Duty Platform

Built with solid, unperforated galvanized steel wave plates for strength and durability.

Side-mounted integral bent curbs keep vehicles securely in position.

Inverted U-shaped reinforcements on the underside ensure lateral stability.

✅ Robust Hydraulic System

Chrome-plated hydraulic cylinder rods resist rust and wear.

Hydraulic pump and motor are managed by a 24V relay and valve set, ensuring precise control and reliable lifting.

The system maintains a consistent, safe lowering speed, even under varying loads.

✅ Emergency Operation

In case of power failure, an emergency manual pump allows safe platform lowering without electricity.

✅ Safety First

Built-in overload prevention circuit limits operation to a maximum load of 2.7 tons (2700 kg).

Advanced posi-lock double lock-down system keeps the platform securely locked, whether operated hydraulically or electrically.

A planar laser system and mechanical safety lock further enhance operational safety.

✅ User-Friendly & Secure Controls

Comes with a CE-standard key switch controller, providing controlled access and added security — ideal for self-parking facilities.

📌 Why Choose the TP-270?

The SolidParking TP-270 combines engineering excellence, safety, and usability in a compact package. With its durable construction, advanced hydraulic technology, and multi-layer safety features, it’s a smart choice for developers and property owners looking to maximize parking capacity while ensuring peace of mind.