When investing in a four-post car lift—whether for commercial, residential, or dealership use—safety is not optional. Today’s top-tier lift systems do more than raise vehicles—they’re engineered with redundant safety locking mechanisms that deliver peace of mind with every cycle.

One standout innovation is the dual safety locking system, a feature increasingly adopted in premium four-post lifts. Let’s explore what it is, how it works, and why it’s essential in modern lift design.

A dual safety locking system refers to two independent locking mechanisms integrated into each column of a four-post car lift. These locks operate as redundant safety layers that protect against power failure, cable slack, or mechanical wear.

Also see comparison between Two-Post VS Four-Post

[ Vehicle Platform ]

||||

┌───────────────┐

│ │

│ Column A │

│ │

│ [EM Lock 🔒] │ ← Electromagnetic Lock (primary)

│ │

│ [Cable Lock 🛡️]│ ← Cable Safety Lock (secondary)

└───────────────┘

Each column (A, B, C, D) contains:

🔒 Electromagnetic lock – activated by power

🛡️ Cable lock – spring-loaded mechanical backup

[ Column Wall (Black) ]

│

▼

┌──────────────────────────┐

│ │

│ Wire Rope │

│ Anti-Loosening Lock │ ◀ 🛡️ Spring-loaded mechanical backup

│ (Cable Safety Lock) │

│ ▲ │

│ │ Catches column │

│ │ in case of rope │

│ │ slack/breakage │

│ │

├──────────────────────────┤

│ │

│ Electromagnet Lock │ ◀ 🔒 Electrically activated primary lock

│ (Power-Controlled) │

│ ▼ │

│ Engages into notch │

│ during lift operation │

│ │

└──────────────────────────┘

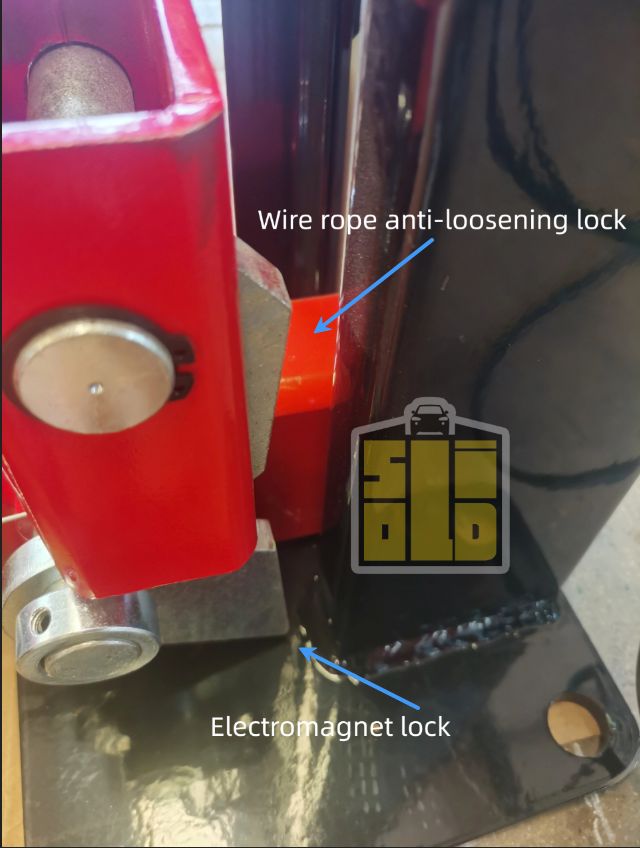

· Powered by an electromagnetic actuator.

· Controls a solid steel locking block that fits into a precision-machined notch on the column.

· Engages automatically during lifting and remains locked until the lift is instructed to descend.

· Wired in parallel across all four columns:

→ If one electromagnet fails, the remaining locks continue to hold the platform securely.

· Spring-loaded mechanical block positioned above the primary lock.

· Designed to catch instantly into safety holes on the column if a wire rope goes slack or breaks.

· Operates independently of power — continues to function during electrical failure.

· Engages with zero lag time in emergency descent scenarios.

This passive lock is what prevents sudden freefall — and is often listed in OEM specs as a “wire rope anti-loosening lock.”

| Feature | Electromagnet Lock  (Primary) (Primary) | Wire Rope Lock  (Secondary) (Secondary) |

|---|---|---|

| Activation Type | Active (electric) | Passive (mechanical) |

| Engages When? | During lift-up operation | When cable slack or break is detected |

| Power Source | Requires electricity | No power needed |

| Location on Column | Lower position | Above primary lock |

| Role in System | Everyday safety hold | Emergency fail-safe catch |

| Shared Across Columns? | Yes (wired in parallel) | Yes (1 per column, independent) |

· Redundancy: Two separate systems mean one can fail without risk to safety.

· Peace of Mind: Critical for stacked vehicle parking, valet platforms, or long-term vehicle storage.

· Code & Compliance: Aligns with ISO standards and best practices in mechanical parking systems.

A classic car collector installs a four-post lift in a compact garage. The dual locking system ensures his valuable vehicles stay suspended—even if power fails or the cable wears down over time.

A hotel uses multi-level parking lifts to stack cars. In such environments, four-post lift safety mechanisms protect both vehicles and nearby pedestrians.

Technicians rely on secure locking while working under raised vehicles. The redundant column locks provide peace of mind for mechanics performing diagnostics or wheel alignments.

Redundancy in mechanical systems—especially safety-critical ones like vehicle lifts—is more than a feature. It’s a safety philosophy.

If a power surge disables an electromagnet, the mechanical spring-lock steps in. If cable tension is compromised, the anti-loosening lock engages instantly. In both cases, the system remains fail-operational, not fail-safe.

This is the gold standard for reliable car parking lifts in modern architecture and design.

You may never see the dual locking system in action—but that’s the point. It’s always working in the background, silently ensuring that your lift holds up under pressure, wear, or failure.

If you’re specifying a lift for your project, the question isn’t just “how much can it lift?”—it’s also “how does it protect itself and your vehicle if something goes wrong?”

With a dual safety locking system, the answer is simple: with intelligence and reliability.